Harman PF100 & PF120 Wall Thermostat: 3-20-08101 Harman

$ 169,99 $ 68,00

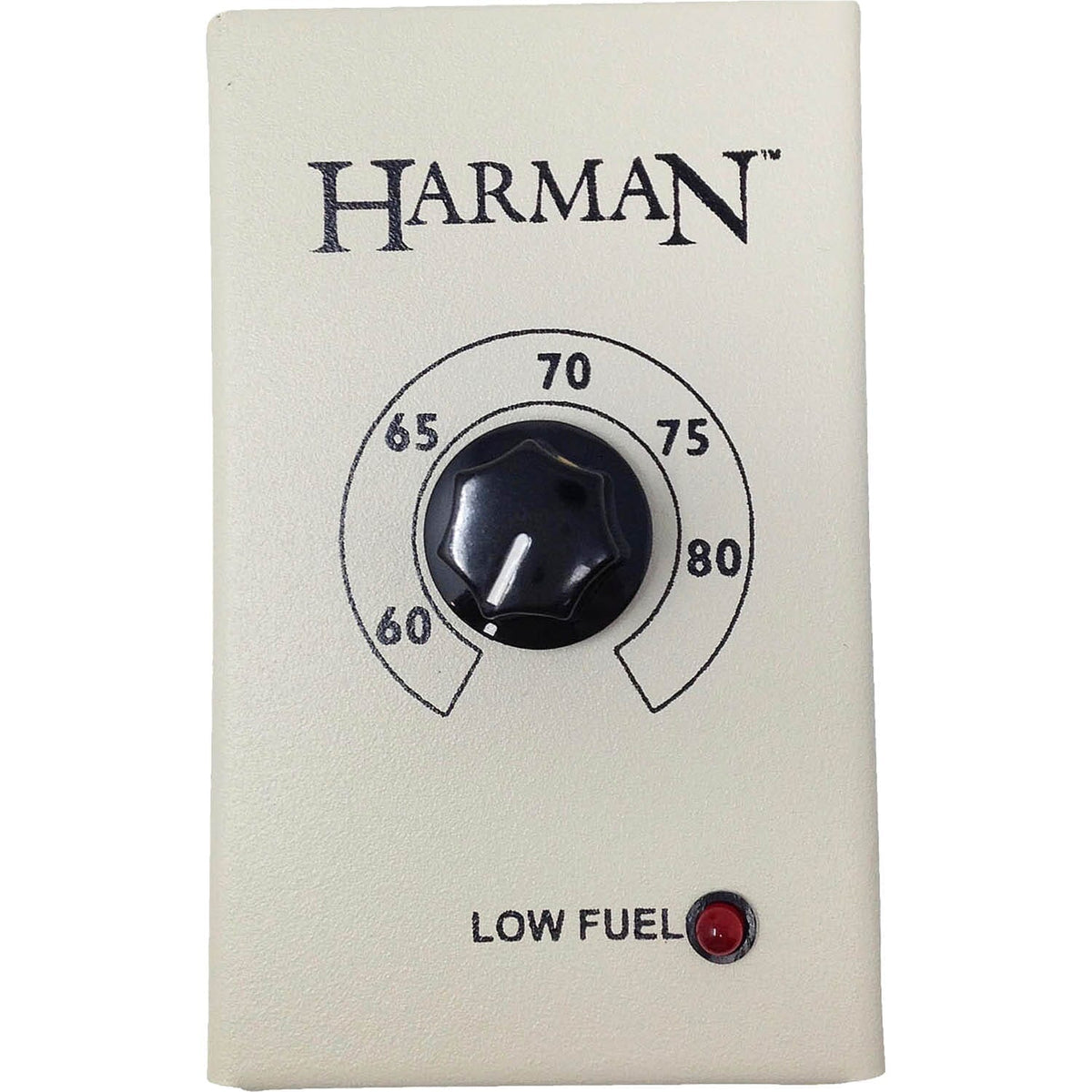

Replacement wall-mounted thermostat for Harman PF100 Pellet Furnaces.

Wall Control

The wall control acts like a thermostat, a thermistor in the wall control is sending temperature information back to the microprocessor on the furnace. This information is used to determine the need to increase or decrease the size of the fire according to the temperature demand.

Setting The Room Temperature

To set the room temperature, simply turn the temperature dial to the desired setting. The control and the furnace will then perform to achieve the set temperature. Note: The minimum temperature you can set with a full counter-clockwise knob position is 58 degrees. The maximum temperature you can set with a full clockwise knob position is 90 degrees.

Wall Control calibration

The “Normal Setting” on the Temp Dial of the Furnace Control (See Fig.44) calibrates the Wall Control temperature span. If the Temp Dial is not pointing to the “Normal Setting”, the temperature span could vary by 3 degrees up or down depending on the Temp Dial knob setting.

Low Fuel Sensor

There is a low fuel sensor in the hopper that tells the control that the fuel level in the hopper has dropped below the sensor. When this happens, the Low Fuel light on the Wall Control will start to blink. You then know that it is time to fill the hopper with pellets.

Note: Testing the low fuel sensor can be done by turning the FEED ADJUSTER knob to “Test”. The POWER light will go off when the sensor is uncovered and will light when the sensor is covered again.

Note: The LOW FUEL light on the Furnace Control will light at the same time. Only the LOW FUEL light on the Furnace Control will remain lit for three minutes after the sensor is covered with pellets. See Note below.

Note: The Low Fuel light indicates that there is power going to the auxiliary leads in the circuit breaker junction box. (120 VAC 60 Hz Max. 1 Amp.)The auxiliary power leads could be used if a bulk hopper and auger system were installed. (see wiring diagram on page 36)

Type of Fuel

Pelletized wood only.

Note: The lower the ash content of the pellets means less heat exchanger surface cleaning that will be needed. The cleaner these surfaces are kept, the more efficient the furnace will be.

Fast Shipping and Professional Packing

Through our long-term relationship with UPS, FedEx, DHL and a variety of other world-class carriers, we are able to offer a variety of shipping options. Our warehouse staff is extremely skilled and will package your products according to our exact and precise specifications. Your items will undergo an extensive inspection and will be properly secured before they are delivered. Each day, we ship to thousands of customers across different countries. Our determination to be the biggest online retailer around the globe is evident by this. We have distribution centers and warehouses located in Europe and in the USA.

Orders with more than one item are assigned processing times in accordance with the item.

We will thoroughly inspect all products before they are shipped. Today, the majority orders will be sent within 48 hours. Expected delivery time is between 3-7 days.

Returns

We are not able to control the inventory in our warehouse and factory. Stock levels can fluctuate at any moment. Please be aware that it's possible that your order will be out of stock after you have placed the order.

The policy is 30 days. If 30 days have passed in the past since you purchased and we are unable to offer an exchange or refund.

For your item to be eligible for return the item must not be opened and in the condition you received it. The item must be in its original packaging.

Related products

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Cleveland Iron Works Hopper Sensor Microswitch: 66617 Cleveland Iron Works

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Avalon Wire Adapter For the 250-00538 Combustion Blower Avalon

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Breckwell 1 Amp Fuse for Control Board C-E-4000: 125032 Breckwell

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Breckwell Fuse Fits Most Models, 5A 125V: C-E-046-N Breckwell

Pellet Stove > Parts > Fuses & Misc. Electrical

10 Amp x 20mm -250V Ceramic Fuse (FUSE-17) Stove Parts For Less

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Breckwell Universal Wire Harness For Digital Boards: (C-E-UH1000) 80675 Breckwell

Pellet Stove > Parts > Fuses & Misc. Electrical

Castle Pigtail Leads Harness for Vacuum Switch: 11392 Castle

Pellet Stove > Parts > Fuses & Misc. Electrical

Avalon Start Switch for 1990 – 1996 Model Pellet Stoves: 90-0511 Avalon

Pellet Stove > Parts > Fuses & Misc. Electrical

Ashley AP130 Pellet Stove Main Wiring Harness: 80548-AMP Ashley

Pellet Stove > Parts > Fuses & Misc. Electrical

12″ Wire Extension Connector. Extends current terminal 12 extra inches. Stove Parts For Less

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Austroflamm Pellet Stove Fuse (3.15 Amp): 16-1023 Austroflamm

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical

Pellet Stove > Parts > Fuses & Misc. Electrical